Loomy Tunes

Loomy Tunes

Tuesday, April 16, 2024

All the Colors of the Rainbow

This morning I brought in a sample card from Maurice Brassard yarns. Marie and I poured over all of the pretty colors, 81 to be exact. We have many colors of weaving cotton on hand but this brand has some shades that we do not have, but we need to see if there is a discount for large orders.

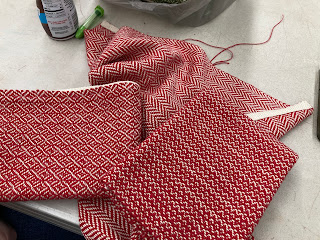

While I was looking at the orders I caought sight of the colors we already have on the looms here at the Weaving Center of the Appalachian Arts Craft Center in Norris,TN. These warps are a lot of different items, at different stages in the warping/weaving process. There are Scarves,Shawls, towels, blankets and bowl cozies. Are you ready?

Now it is time for Show and Tell! Marilyn had been seeing a knitted Chicken online and just had to try the pattern, she loves it! Carol finished the edging on Phyllis's crochet bedspread (that her Aunt had almost finished), once it gets a good wash she will put it on a bed at her house.

Liz brought in her latest Baby blanket and Shannon found in her stash a Crown Price-O-Matic that was used during the depression to calculate how much to charge for mending clothes.

Laura brought in a shawl that she had finished with a french seam, and Patty brought in a shawl warp she had cut off last week and a towel that combines point twill and bumberte.

One more colorful warp that is still on the board!

That is it for this week, as always this is Tina, for all!

Tuesday, April 9, 2024

Reluctant Serger and Project Progress

We had a very reluctant member of the team this morning! The auto threading mechanism didn't want to work and it seemed like it was blocked! After rereading the instructions it became apparent that we read them wrong the first time, now all is well!

Here are some progress pictures on the looms. Chris is threading her project and on the loom next to her one of the other new weavers is already weaving.

Joycelyn is threading her colorful warp and Bonnie is almost ready to start weaving her towels!

Mark is threading the warp we put on last week and John Paul is working hard to finish the warp on the Studio Rug loom so that we can put another 40-60 yard warp on it!

Now it is time for Show and Tell! Dana has been away for a little while, so she has a lot of show and tell today. First she has a warp chain that her son dyed on dye day and one that she dyed at the same time, then she has a towel project that she wove while she was away.

Shannon brought in some curtains that she had sewn for Barbara, and Barbara brought in shawl project she has just finished, and she and Carol are going to put on the finishing touches.

Betsy finished some towels this week and it was a stash busting project! She ran out of weft on the third towel and had to substitue a similar color, then for the 4th towel she chose black as the weft. Mark brought in a couple of napkins he wove this week, he was surprised how much the napkins shrunk in the wash.

Last week I had already published the blog and I received an email from Patty about one of the students in the evening rigid heddle class. This is Sylvia with her towels. This is only her second project on the rigid heddle loom!

That is all I have for this week, as always this is Tina for all!

Tuesday, April 2, 2024

So Many Pretty Warps

It has been awhile since I gave you a peek at all the pretty projects in process, so that is the first thing I will do!

Warp and woven project!

Phyllis is working on a beautiful warp!

Shirley is loving her towel project!

Liz is threading her loom, and here is a lovely shiny warp on one of the table looms.

Betsy is working on her color and weave gamp, she likes the yellow weft so far.

I caught Liz number 2 threading a sample warp, and after I left today they sent me a picture of Patty cutting the warp off of her loom.

On the kitchen counter today was a donation that we chose things for our very own and the rest will be going to a charity we know that loves this craft stuff.

My job today was to put a 60 yard warp on the Leclerc Mira. The only way we can do such a thing is with a sectional warp beam, a tension box and a spool rack. By lunch time I had 3 @ 60yard sections wound. We timed winding the third section and it took all of 3 minutes to wind 60 yards!

Now it is time for Show and Tell!!! Phyllis brought in a crochet bedspread that her Aunt (I think) worked on and almost finished. Someone will finsh the edging and it will get washed and admired! Mark brought in a stack of 18 placemats that he had taken off of the loom last week!

Here is the pile of finished projects that are going upstairs to the shop this afternoon. Did you see Mark's placemats and Jenny's T-shirt rugs?

By 2:00 I had finished the warp on Mark's loom, and since the loom right next to it is going to need a new sectional warp in a week or 2 I just left my tension box and spool rack there.

That is all for this week, as always, this is Tina, for all

Subscribe to:

Posts (Atom)